The LOGISTEED Technical Center, located in Chiba Prefecture, Japan, is our own unique facility, solely specialized in packaging analysis and its optimization.

After we develop a packaging material, we test quantitatively and qualitatively, using a variety of testing equipment and instruments. The packaging material's property is checked through various tests such as tension, compression, rupture, etc., and also verified for the vibration and shock that can occur in such transportation modes as trucking and railway. We investigate matters occurring in packaging, transportation and storage by tests conforming to JIS, ASTM and UN standard. We also support your needs for product evaluation. Please feel free to contact us for more information.

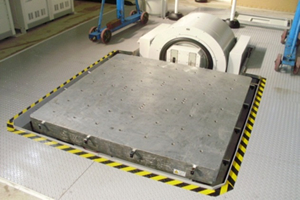

Investigates the vibration characteristics reproduced by various transport modes such as trucking.

| Model | DS-3000-15L |

|---|---|

| Table size | 1,500 mm x 1,500 mm |

| Excitation force | 30 kN |

| Loadable mass | 500 kg * |

| Excitation method | sine wave/random wave |

| Maximum displacement | 51 mm p-p |

| Frequency range | 2 ~ 200 Hz |

| Direction of excitation | vertical/horizontal (1 axis) |

Carries out stacking strength tests and strength investigations of packaging materials during storage.

| Model | UH-C100kNX |

|---|---|

| Mountable size | 1,500 x 1,500 x 2,000 mm |

| Maximum load weight | 100kN |

| Maximum stroke | 200 mm |

| Loading rate | ~ 50 mm/min. Controllable depending on weight |

| Remarks | End work possible by load and displacement control |

Reproduces incidents where small items are dropped during manual handling, pallets fall off from a forklift, and so on.

| Drop method | arm type | hanging type |

|---|---|---|

| Model | DTS-50 | EMH-500 |

| Droppable size | 900 x 500 x 900 mm | 3,000 x 2,200 mm |

| Droppable mass | 50 kg | 500 kg |

| Drop height | 200 ~ 1,200 mm | depends on ceiling height and product height |

| Drop attitude | Jig used, diagonal drop possible | held at one side, free drop possible |

It corresponds to material investigation such as cardboard and PP band.

| Model | AGS-10kNX |

|---|---|

| The maximum load weight | 10kN |

| Maximum stroke | 200 mm |

| Loading rate | ~ 50 mm/min. Controllable depending on load |

| Applicable tests | Compression test Tension test |

It reproduces transport environments, typical of inside ocean freight containers, such as high temperature and high humidity, temperature drops, etc.

| Name | Environment test chamber A | Environment test chamber B |

|---|---|---|

| Chamber size | 3,400 x 1,900 x 2,400 mm | 3,480 x 2,580 x 2,500 mm |

| Caliber size | 1,800 x 1,800 mm | 850 x 2,200 mm |

| Maximum storage mass | 1,000 kg | 500 kg |

| Temperature control range | -30 ~ 80°C | 20 ~ 23°C |

| Humidity control range | 10 ~ 95%RH(10 ~ 80°C) | Standard condition (50 ~ 65% RH) |

Prototypes packaging material according to CAD drawings.

| Format | AS2616F |

|---|---|

| Cut size | 1,600 x 2,600 mm |

| Cut depth | Cardboard 15 mm Plastic cardboard 5 mm Expanded foam 65 mm |

| Functions | full cut/half cut ruled line/pen insert |

Records acceleration value of vibration and shock for transport testing, etc.

| Model | SAVER9X30 | DER-1000 |

|---|---|---|

| Measurement channels | 9 ch (3 main, 6 external) | 3 ch |

| Method of measurement | Single trigger, time trigger | Single trigger |

| Sampling rate | 50 ~ 10,000 points/sec | 1024, 2048 points/sec |

| Maximum measuring acceleration | 200 G | 50 G |

| Temperature and humidity measurement range | -40 ~ 60°C (5 ~ 95% RH) | -20 ~ 60°C (0 ~ 100% RH) |

SAVER3X90

DER-1000

We can arrange transportation vibration measurement, using the driving training course adjacent to our Technical Center.

Records the temperature and humidity as found in transportation tests etc.

| Model | TR-71U | TR-72U |

|---|---|---|

| Measurement object | temperature | temperature/ humidity |

| Measuring range | -40 ~ 110°C | 0 ~ 50°C 10 ~ 95% RH |

| Measurement interval | 1, 2, 5, 10, 15, 20, 30 secs 1, 2, 5, 10, 20, 30, 60 minutes total 15 passes |

|

TR-71U

TR-72U

An acceleration sensor is installed in the product, to measure the amplification of the acceleration value.

Excitation conditions: JIS Z0200/random vibration

Verify the humidity degradation of a cardboard box under standard conditions and one pre-treated for high temperature and high humidity.

Compression speed: see JIS Z0200

Pre-treated conditions: see JIS Z0203

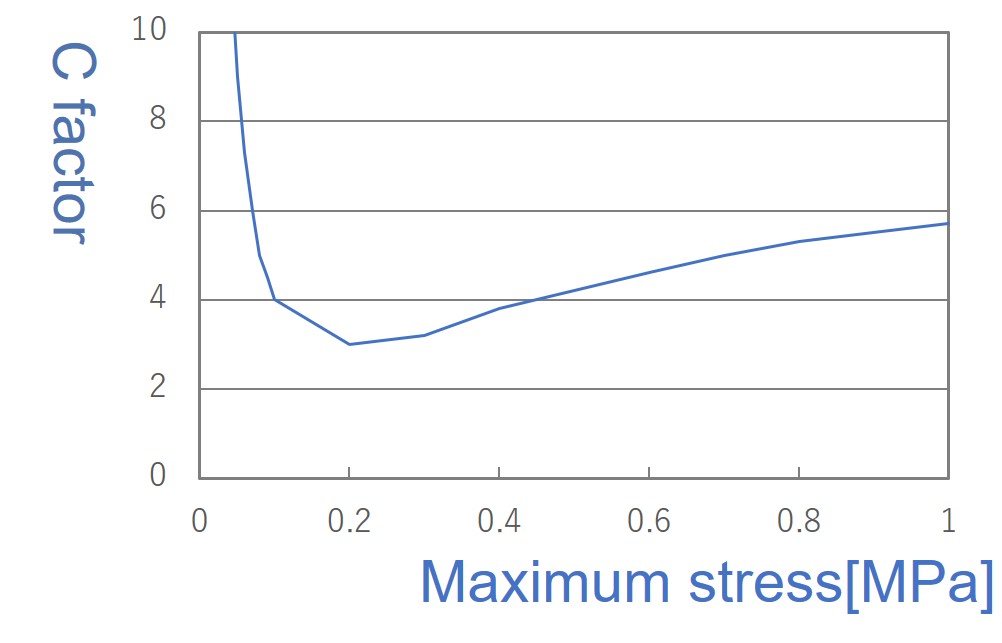

As per the result of compression test performed on foam material the cushioning characteristic (C factor) is calculated which will be used for foam cushioning design.

In order to study trucking environment differences between China and Japan, we installed a recorder to trucks for measuring vibration trends.

A dummy product and transportation environment recorder housed in a cardboard box, to investigate impact generated at the time of actual transport and transport within the warehouse.

Document request related to Technical Center, please feel free to contact us with any questions.

Our Service Portfolio