August 31, 2023

LOGISTEED, Ltd. is pleased to announce that “Switching from wooden box to cardboard box for elevator parts” won the Technical Packaging Award, and “Transportation packing box with the slope for reagent exchange robot” won the Large/Heavy Goods Packaging Category Award at the Japan Packaging Contest 2023 held by the Japan Packaging Institute.

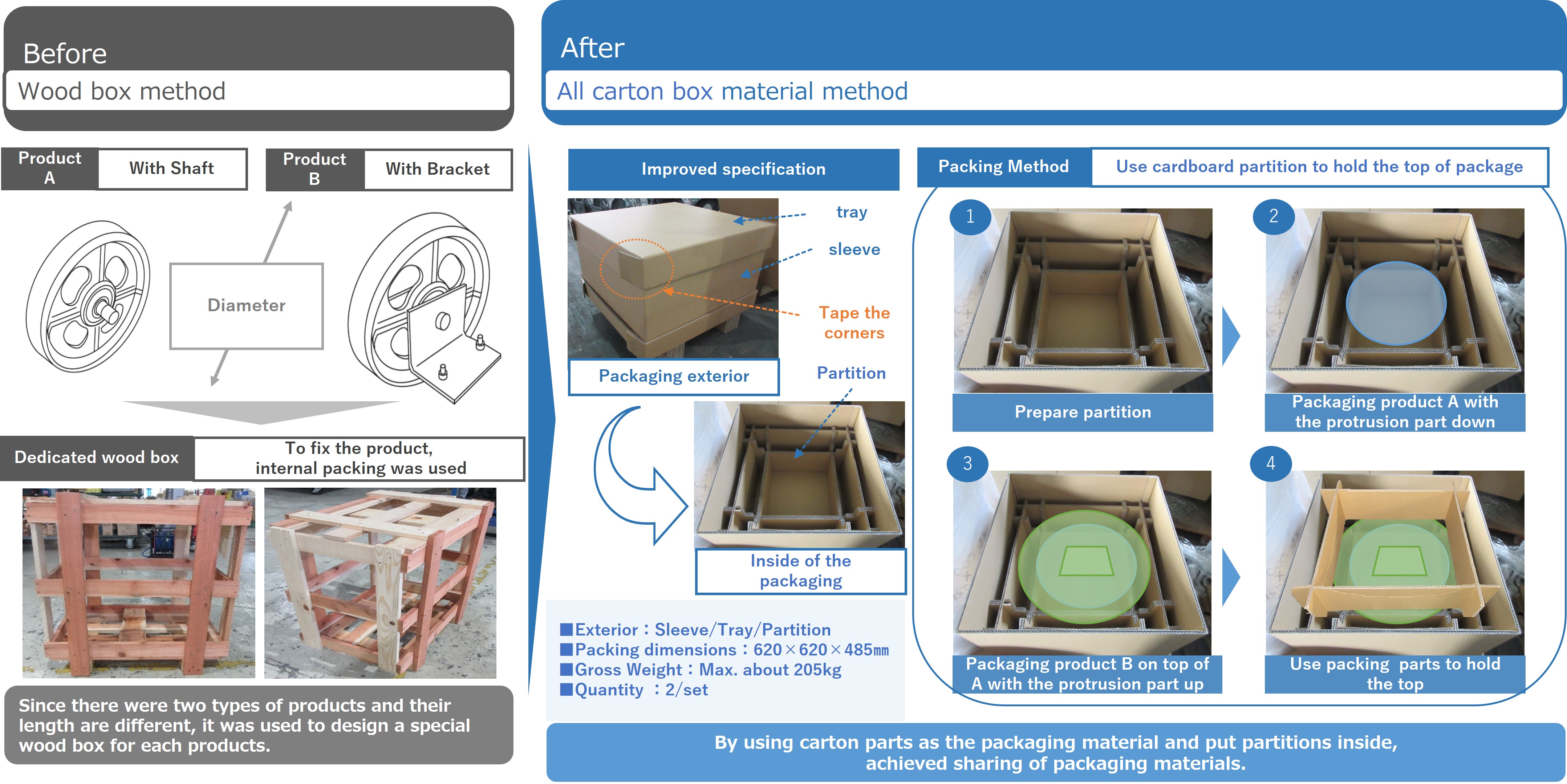

The elevator parts to be packaged are a set of two types of products, one with a shaft and another with a bracket, and they were previously packaged in wooden boxes. Since the two products have different dimensions, we had to create wooden boxes to fit each of them. So there were issues such as an increase in labor hours for packaging. Then, we worked on the development of new packaging that can be packed two products with different dimensions together. The developed packaging consists of four parts: a sleeve, a tray, a partition, and an upper pressing packing, all of which are made of carton box material. Since it is no longer necessary to create a wooden box for each product, the labor hours required for packaging have been reduced by 50%. Also, it has reduced the labor hours for packaging disposal by 20% by using tape instead of stitching(*)on the edges of the carton at the four corners of the tray. Furthermore, we successfully reduced CO₂ emissions generated in the process from procurement of packaging materials to disposal by 43%.

(*)stitching closure

A method of fastening metal needles using a large stapler when assembling carton box.

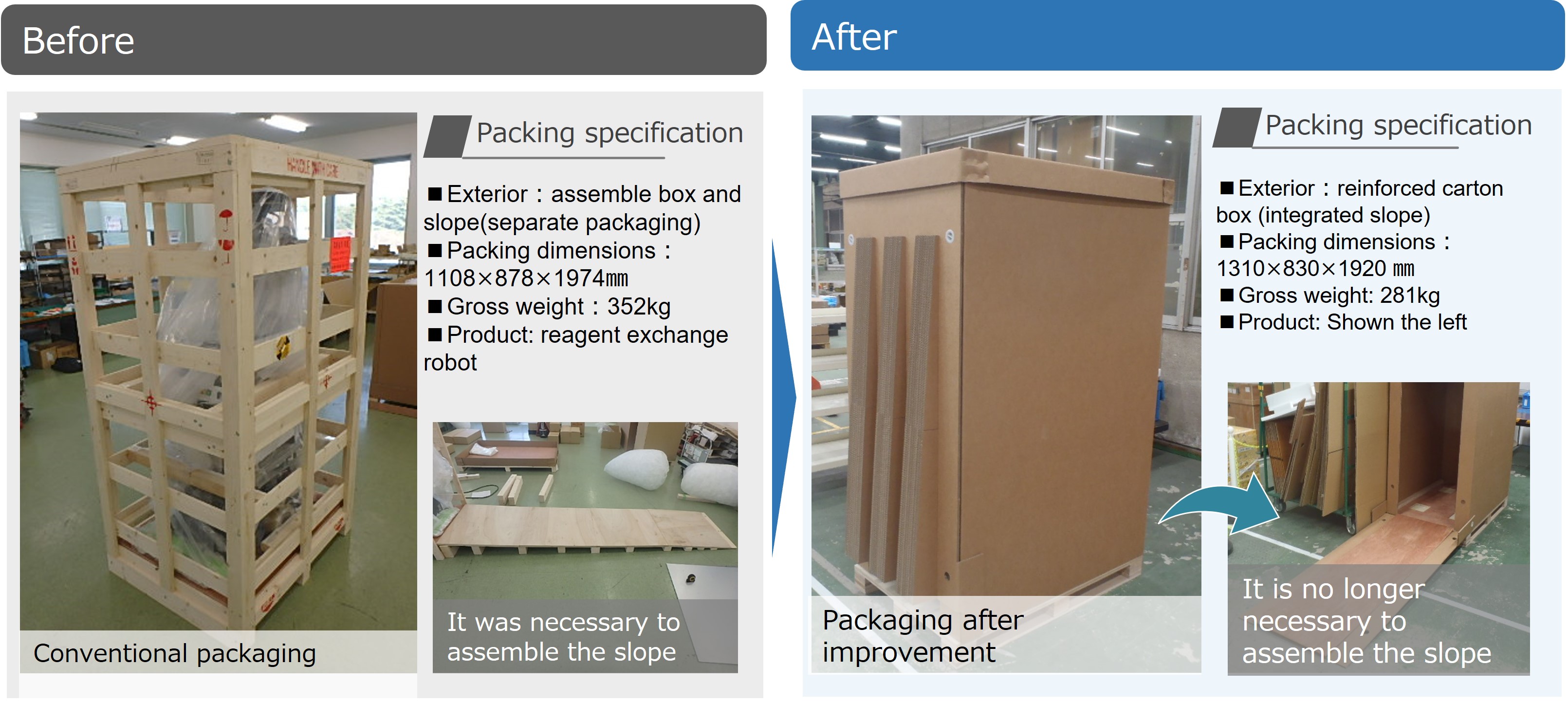

Conventional wooden transportation packaging had issues, such as the need to assemble a slope for unpacking, and the time and cost required to dispose of them. To solve these problems, we developed a transportation packaging using reinforced carton box. The biggest feature of this specification is that a slope, which was packaged separately, is installed on the front of the packaging box, and the products can be removed by simply flipping the slope down. Previously, forklift held a pallet from two directions, but the shape of the pallet was changed so that a pallet could be hold from four directions. As a result, it became easier handling. Also, plywood is used inside of the box. It made the slope strengthen and the stability improved. After those improvements, we have reduced the number of unpacking steps by 50% and the CO₂ emissions generated from the procurement of materials to the disposal of packaging boxes by 90%.

Under the business concept “LOGISTEED,” we aim to become the most preferred global supply chain solutions provider, and we strive to achieve new innovations by enhancing the core domain and expanding collaborative area across businesses and industries.

・LOGISTEED packaging solution

https://www.logisteed.com/en/solution/packaging/

Our Service Portfolio