We at the LOGISTEED Group respond precisely to a variety of your challenges in the packaging area, whether it concerns package design, packing work, or material procurement.

Our strength comes from our unique know-how, which has advanced with our experience on numerous package designs for many major manufacturers' products over the years, as well as our packaging R&D at the LOGISTEED Technical Center.

The LOGISTEED Technical Center in Matsudo City, Chiba Prefecture, is our own facility specialized in packaging analysis and optimization. It has evaluation equipment and measurement devices for conducting logistical tests. We can also run simulations of possible hazards that may occur during transport, to propose the best packaging solution based on abundant quantitative data and evaluation test results.

We propose the best packaging from a holistic standpoint - we not only examine product materials (in terms of resistance against water/moisture, rust, and temperature, hazardousness, and strength), but also consider delivery conditions (such as transport routes, storage conditions, and the climate) as well as the complexity and cost efficiency of packing and disposal.

Our solutions include buffer designs to control the impact within the allowable value, vibration-proof designs to avoid the resonance range, temp-controlled packaging to retain the allowable temp range during transport, dangerous goods packaging in compliant with laws/regulations, and returnable containers to withstand repeated usage.

We efficiently perform verifications through various tests as per your requirement, to provide one-stop solutions for operational improvement.

By outsourcing all packaging work from design, prototyping, evaluation testing, up to material procurement, you will be able to concentrate on your core business.

If specifically said, we follow the proper packaging flow of inspection and design in accordance with "Packaging 5-STEPs", firstly understanding (1) product strength analysis, (3) logistics environmental data, (4) packaging material data and accordingly (2) we decide packaging design and select packaging material. (6) By assuming the conditions in distribution environment, (5) quantitative evaluation of packaging and transportation tests are done, and finally we provide the optimal packaging design.

The logistics environment adds a variety of stresses. With such, your valuable product may be damaged or its quality can deteriorate during distribution, resulting in an adverse impact on customer satisfaction and operational efficiency. That's why it is vital to pre-assess your logistical environment and apply packaging that can withstand your specific conditions. We always aim for proper packaging, to protect important products of yours.

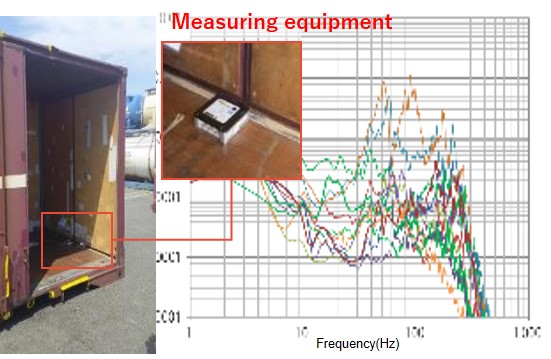

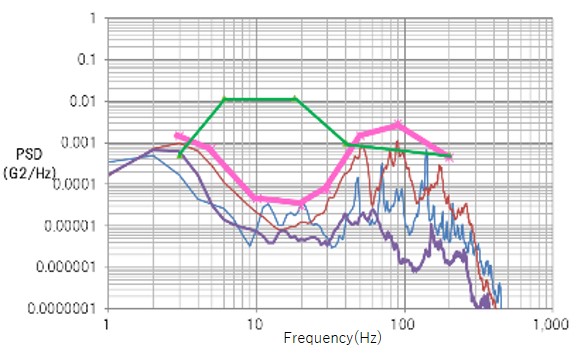

In order to eliminate quality concerns caused by switching the transportation mode of precision equipment, we have formulated packaging test conditions that are suitable for domestic railway transportation, and have implemented packaging design to withstand them.

We achieved a modal shift (switching to rail transportation) and contributed to customer CSR compliance also at the same time transportation cost reduced.

1. Measuring conditions of Railway transportation.

2. Creating a tester compatible program.

3. Actual transportation test, packaging improvement.

4. Packaging test in railway transportation program.

The overseas standard of conventional corrugated board is weaker than that of Japan, when stacking it was common to see the deformation made to the lowermost part of the box, thus damaging the inner contents.

Therefore, in our technical center we conducted a compression strength test of overseas L shaped paper pillar, confirming that it could sufficiently reinforce the existing overseas corrugated board. Thus, by arranging L pillar inside the four corners of carboard we overcame the occurring damages.

1.Before improvement (overseas made bottom corrugated cardboard.)

2. Compression test of L shaped paper pillar.

3. After improvement (L shaped paper pillar are placed in the four inner corners)

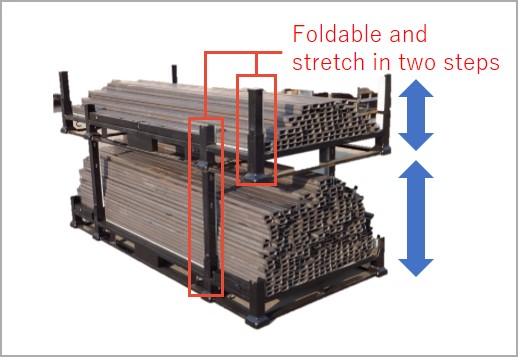

Conventional pallets used for transportation and storage of construction materials have had problems with poor loading efficiency due to their invariable height, inability to be folded, and storage efficiency and management due to the use of discrete parts.

By changing to height variable pallets and thoroughly eliminating the use of discrete parts, we have pursued workability, functionality and efficiency.

Before improvement

After improvement

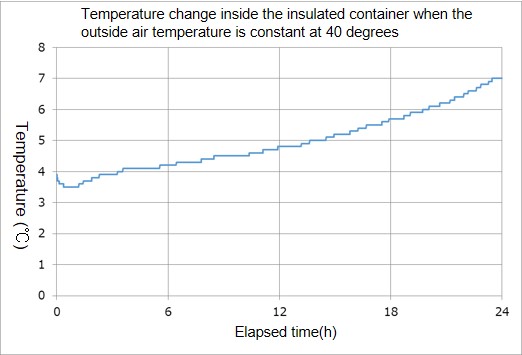

Development of thermally insulated box/temperature controlled box (used to maintain constant temperature.)

Thermally Insulated box

Test result

Please feel free to contact us for advice or quotes, etc.

Our Service Portfolio