Environmental Activities

- Environmental Initiatives

- Environmental Protection Action Guidelines

- Environmental Action Plan

- Environmental Activities

- Reduce Environmental Load Generated at All Our Places of Business

- Providing Logistics Services with Less Environmental Load

- Improve Eco-Mind Level and Enhance Eco-Management System

- Promote Symbiosis with Nature and Environmental Communications

- Environmental Data

Reduce Environmental Load Generated at All Our Places of Business

The Group is working to reduce environmental load generated at our sites by actively introducing eco-friendly vehicles and energy-saving devices for the realization of decarbonization in the business processes. The energy consumed by our group includes electricity (approximately 70%) and fuel (approximately 30%), and we taking the following measures for energy saving and global warming.

Energy saving and global warming countermeasures implemented in buildings

Introduction of LED lighting fixtures

We are proactively installing LED lighting fixtures in new logistics centers and offices. We are also replacing existing fluorescent/mercury lights with LED lighting fixtures in the existing facilities and will continue until the replacement is completed in all facilities.

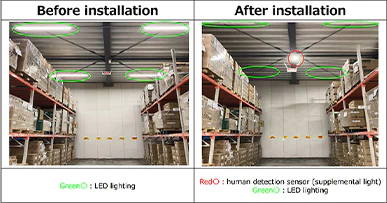

Using human detection sensor

Chukyo Logistics Center in Aichi Prefecture is working on power saving by using human detection sensor. To reduce power consumption by lights in the storage room when it is unmanned, we installed supplemental lights with a human detection sensor between storage shelves which light when the sensor detects the presence of workers picking up or storing products, achieving both workers' safety and power saving.

Procure renewable energy

Renewable energy

We are actively switching electricity used at our offices to electricity generated from renewable energy. In FY2023, we switched to electricity generated from renewable energy at 104 sites, a significant increase from the 17 sites in the previous year. Of the 104 sites, 25 sites, including the Matsudo Training Institute and the Track and Field Club's club house, achieving zero CO2 emissions by applying the 100% renewable energy plan.

Non-fossil Fuel Energy Certificates

At our headquarters building, we procured non-fossil fuel energy certificates from the market to offset emissions, achieiving a net-zero CO2 emission status.

Introduce solar power generation equipment

In-house consumption type solar power generation equipment has already introduced at six bases, but we are considering introducing it at other bases as well.

Installment of solar panels on the roof of logistics centers

VANTEC KYUSHU LOGISTICS CORPORATION, our group company, has installed solar panels on the roof of its logistics center in Fukuoka Prefecture. The center expects that the introduction of solar power generation In FY2023, we reduced CO2 emissions by 15 tons.

CO2 emission reduction by such as energy saving and energy creation in buildings

| CO2 emission reduction from buildings (electricity) | FY2023 Target | FY2023 Result |

|---|---|---|

| YoY -2% | -11.2% |

Energy saving and global warming countermeasures of vehicles

The Group strives to reduce CO2 emissions generated by vehicle fuel through such initiatives as the introduction of the advanced eco-friendly vehicles, promotion of eco-friendly driving and promotion modal shift.

Making the shift to eco-friendly vehicles and encouraging eco-friendly driving

We are promoting the shift to eco-friendly vehicles (highly fuel efficient, low-pollution vehicles). We achieved the eco-friendly vehicle ownership ratio of 100% at the end of FY2016, except for certain special vehicles. We will further promote the shift to the advanced eco-friendly vehicles with higher environmental performance in order to reduce air pollutant emissions and will also promote eco-friendly driving, etc. to reduce environmental load.

Eco-friendly driving with the introduction of SSCV-Safety

"SSCV-Safety", developed independently by us, has been introduced to all domestic group vehicles. This will not only prevent traffic accidents, but also to improve fuel efficiency through eco-friendly driving. SSCV-Safety detects in real time near-miss incidents such as sudden braking and steering due to insufficient distance between vehicles as well as driver fatigue, alerting the driver to help prevent accidents. The system also records daily driving data along with video images for use in safe driving guidance. Since sudden braking, sudden steering, and sudden acceleration can lead to a decrease in vehicle fuel efficiency, alerts issued while driving and safe driving instructions after exiting the vehicle have the aspect of promoting eco-friendly driving, which also contributes to improving vehicle fuel efficiency.

Introduction of double-trailer trucks

Vantec Central Logistics Corporation, our group company, introduced and operates two sets of 21-meter long double-trailer trucks under the "Project to promote CO2 emissions reduction measures in the transport sector" which is a joint project by the Ministry of the Environment and the Ministry of Land, Infrastructure, Transport and Tourism. The company has continued this project since FY2019 and will expand operation routes to further improve logistics efficiency.

FY2023 result

| Introduction vehicle | Two sets of 21-meter long double-trailer trucks |

|---|---|

| Operation route | From Fuji city, Shizuoka Prefecture to Nantan city, Kyoto Prefecture |

| Start operation | Trial operation in February 2019, Actual operation from August 2019 |

Electrification of transport vehicles

The Group is proceeding to introduce electric vehicles and fuel cell vehicles to reduce the environmental impact of transportation while monitoring market trends. By the end of FY2022, we introduced four electric trucks, and in FY2023, at LOGISTEED East Japan Co., Ltd., we introduced our group's first fuel cell truck (FCV). Into the future, we will continue to expand the introduction of electric trucks and work to reduce CO2 emissions.

Example of overseas implementation

- ESA s.r.o.

In the Czech Republic, emission standards for truck exhausts are tightening in line with Euro 7* regulations, which will come into effect for trucks in July 2027. In this context, group company ESA s.r.o. conducted testing of electric vehicles from various vehicle producers, including the Volvo FM42 tractor and the large electric refrigerated truck Mercedes-Benz eActros 400, capable of transporting 18 pallets. The company carried out trial transports between customer sites and warehouses. The tested trucks have a range of approximately 300 kilometers on a single charge. Due to the current shortage of quick charging stations in the Czech Republic, the tests also focused on evaluating operational procedures, such as monitoring battery charge levels and optimizing route planning. Given the rapid development of electric drive systems for tractors and trucks, ESA s.r.o. anticipates incorporating vehicles with longer ranges into its fleet compared to those tested.

*Euro 7: Exhaust gas regulation applied to automobiles sold in Europe

- VANTEC EUROPE LIMITED

VANTEC EUROPE LIMITED, a group company in the UK, introduced in 2023 seven tractor units that run on hydrogenated vegetable oil (HVO), which is expected to be used more widely as a "next-generation biofuel" that can also make a significant contribution to reducing greenhouse gas (GHG) emissions. Those are being used for last-mile logistics on the 16-mile route from the Winsford distribution and processing site to a manufacturing site in Crewe. We have confirmed that HVO can be used without vehicle modification and that CO2 emissions can be reduced by 100%.

- Transport of consumer electronics from Ibaraki to Osaka Prefecture using 31 foot containers

- Transport of cosmetic products from Kanagawa to Osaka Prefecture using 31 foot containers

- Transport of automotive parts from Fukuoka to Osaka Prefecture using 12-meter trailers

- Transport of steel products from Ibaraki to Osaka Prefecture using 12-meter trailers

- Transport of steel products from Ibaraki to Fukuoka Prefecture using 12-meter trailers

- HTS Receives Advanced Technology Award at the 23rd Logistics Environment Awards (July 6, 2022)

- Eco-Ship Modal Shift Excellent Business Awards 2021 HTS Receives Shipping Modal Shift Grand Prize (May 24, 2022)

- Working hours required for packaging: down 50%

- Working hours for packaging disposal: down 20%

- CO2 emissions: down 43%, etc.

- Working hours for unpacking: down 50%

- CO2 emissions: down 90%, etc.

- a. Training for waste management personnel

- We continue to provide training for employees in charge of waste management aiming at promoting treatment that complies with laws and regulations without fail, leading to proper management of waste and improvement of the recycling rate.

- b. Training for environment management operation

- We have been working to foster environmental awareness by continuously conducting environmental education for new employees, new assistant managers and managers. In FY2022, the education focused on understanding social trends and growing expectations of corporations regarding SDGs and ESG investment, as well as understanding business activities toward decarbonization and sharing of specific examples of activities at each site.

- *1CDP: An international non-profit organization that globally evaluates corporate efforts related to climate change and water.

- *2SBT: Abbreviation for Science Based Target, an international initiative that certifies companies that set ambitious targets that are consistent with the 2-degree goal.

- *3Environmental accounting: A system in which companies, etc. recognize the costs of environmental protection in their business activities and the effects obtained from those activities, and measure and convey them as quantitatively as possible (in monetary units or physical quantities).

- Reporting period: April 1, 2023 - March 31, 2024

- Scope: The Company, domestic group companies

- Reference source: "Environmental Accounting Guidelines 2005" published by the Ministry of the Environment

- Emissions of outsourced transport operation (truck, railway, ship)

- Value of packaging materials purchased

- Value of goods and services purchased

- Number of vehicles for sale procured

- Amount of capital investment

- Amounts of electricity and fuel used

- Emissions during the delivery of vehicles for sale procured

- Amount of waste generated by type

- Business trip expenses

- Commuting transportation expenses paid

- Leased asset (upstream)

- Transportation and delivery (downstream)

- Processing of sold products

- Emissions from the use of vehicles sold

- Volume of waste of packing materials purchased

- Volume of waste of vehicles sold

- Emissions from the use of vehicles leased

- Franchises

- Investments

Energy saving of forklifts

Since FY2021, we have been promoting the introduction of lithium-ion forklifts. Forklifts are indispensable in logistics operation in warehouses, etc. and generally powered by lead battery, but we are trying to reduce energy consumption by shifting to lithium-ion batteries with long cycle life and high charging efficiency. In FY2023, we introduced 31 lithium-ion battery forklifts. We will continue to expand the introduction of lithium-ion batteries and work to make forklifts more energy-saving.

CO2 emissions reduction by promoting the electrification of vehicles

| CO2 emission reduction from vehicles (fuel) | FY2023 Target | FY2023 Result |

|---|---|---|

| YoY -1% | +2.2% |

Providing Logistics Services with Less Environmental Load

We recognize that it is important to work to reduce CO2 emissions and environmental load not only in the Group but also in the supply chains of our customers. Based on this idea, to "provide logistics/services with less environmental load" as set forth in our environmental policy, we are striving to reduce the environmental load and provide new environmental value through our business activities, e.g., development of services that contribute to the reduction of CO2 emissions including Scope 3 emissions from our customers, in addition to ongoing initiatives such as modal shift and collaborative logistics.

Milkrun of automobile parts in North America

Carter Express, a Group company in North America, provides distinctive services that make full use of operational know-how cultivated through experience to date and reliable transportation capacity, such as auto parts transportation by truck within the United States making use of its unique "Shared Milkrun" business model, as well as cross-border transportation among Canada, the United States, and Mexico, which are members of the North American Free Trade Agreement (NAFTA).

For example, joint transportation (Shared Milkrun) in a milk run that collects products from multiple suppliers of multiple customers reduces the number of trucks in operation and mileage, which not only reduces logistics costs but also contributes significantly to the reduction of CO2 emissions in the customer's supply chain.

Promotion of modal shift

Modal shift in Japan

The Group is actively promoting modal shift from truck transport to rail and sea transport with the goal of developing new customers and new routes in order to reduce CO2 emissions and alleviate the shortage of truck drivers.

Newly developed routes and customers (cases)

| Type | Year | Category | Routes/Cases | Details |

|---|---|---|---|---|

| Rail | FY2023 | Route | 2 routes |

|

| Sea | FY2023 | Route | 4 routes |

|

Promotion of overseas intermodal*

We have introduced special containers to promote modal shift not only domestics but overseas and reduce CO2 emissions globally.

For example our Turkish group company Mars Logistics Group Inc. is focusing on unique cross-border transportation, which includes sea transportation from Turkish sites such as Istanbul to Italy, rail transportation from Italy to Luxembourg, and truck transportation from Luxembourg to major cities in EU, and by so doing it realizes high-efficiency and less environmental load, and sustainable logistics.

*Intermodal: Multimodal transportation combining trucks, ships, railroad, etc.

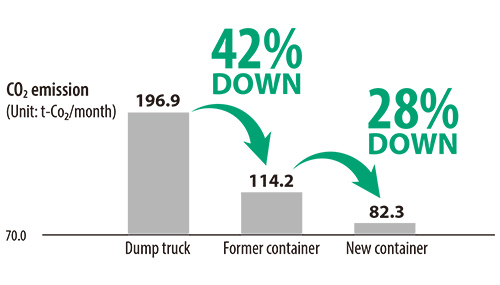

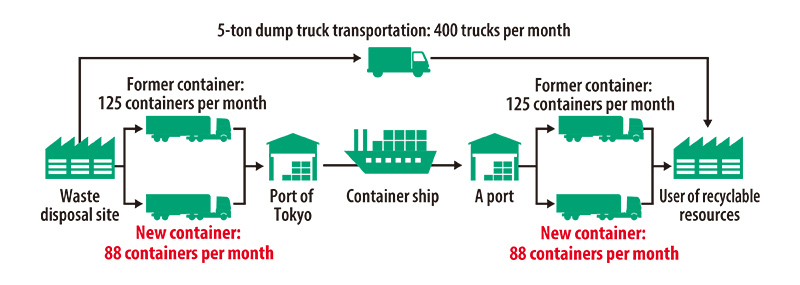

Modal shift of recyclable resources waste transportation

We contribute to the reduction of CO2 emissions by further promoting modal-shift to the sea transport in transporting recyclable materials such as waste plastics segregated from wastes.

We had been implementing a modal shift to transportation with ships using self-developed containers for recycled materials. In FY2019, we introduced new containers and achieved further efficiency improvement.

This is due to the fact that the introduction of new containers has made it possible both to increase load capacity and shorten unloading time, and the number of containers transported has been reduced to about two-thirds each month, and some other factors.

In addition, comparing the CO2 emissions of the case where all processes are transported by dump truck, this means that the reduction is approximately over 40%.

In recognition of these "efforts to improve transportation efficiency of recyclable resource waste transportation by developing special new transportation containers," we received the "Logistics Environment Special Award (FY2019)" at the 21st Logistics Environment Awards.

While problems such as marine plastic waste pollution have been pointed out, we will continue to contribute to solving environmental problems by promoting a modal shift and providing logistics services with less environmental load on the recycling industry.

Transport of product raw materials and finished products utilizing the same marine container

As the shortage of truck drivers becomes more serious, securing stable long-distance transport into the future has become an issue. We are working on modal shift from trucks to coastal vessels for long-distance transport between the Kyushu and Kansai regions in order to ensure stable transport. Due to the switch to coastal vessels, this initiative has resulted in a significant increase in the volume of transport per operation through such measures as cooperative efforts with multiple shippers and other related parties to enable containers for marine transport to also be used for domestic transport and transporting product materials domestically and exporting finished products internationally in the same container. This initiative is not only a response to the driver shortage, but also contributes to the reduction of CO2 emissions by improving transport efficiency.

Reduction in environmental load by opening a joint terminal

The Mito Transport Center, which was opened in Tokai Village, Naka-gun, Ibaraki in February 2021 as part of the major measure of a centralized vehicle assignment center plan, is a joint terminal not only for the Group but also for regional business partners. It has an aim of achieving efficient business operations in the entire transport ecosystem including partners by sharing transport resources in the region (cargo/vehicle information, offices, and garages, etc.).

The introduction of SSCV-Smart, an online system that connects cargo owners and transporters, will enable the center to centrally manage everything from acquisition of transport projects to vehicle assignment, issuing of driving instructions, and billing. The system is thus expected to reduce environmental load through improved business efficiency as seen by effects such as reduction in CO2 emissions and paper usage.

Development of "volume reduction" measures aimed at reducing plastic waste

We have been considering the introduction of "volume reduction" stretch film through collaboration by the environmental management division and the technology development division. Stretch film is used when packing up stacked luggage, etc., but since it is disposed of as waste plastic after use, replacing it with a thinner material can lead to a reduction in the amount of waste plastic generated. It will be possible to maintain functionality as a packaging material and reduce volume at the same time. Therefore, we are aiming at reducing plastic waste by conducting market research and collecting information on stretch films that are thinner than the current one.

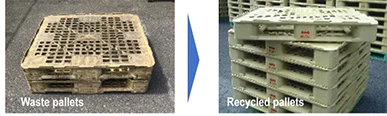

Recycling of plastic pallet

PALENET CO., LTD., our group company engaging in sales and rental of plastic pallets, supplies returned pallets that are broken and no longer usable as materials for new pallets to a recycled plastic pallet manufacturing company in which the company holds a stake, instead of disposing them, contributing to the reduction of waste plastic and the effective use of resources. More than 20,000 waste plastic pallets are recycled every year thanks to this initiative.

Award in packaging technology

The Japan Packaging Contest 2023: LOGISTEED Receives "Technical Packaging Award" and "Large/Heavy Goods Packaging Category Award"

We are working to improve packaging technology and to reduce environmental load including reduction of packaging-related materials and wastes while meeting customers'needs.

In the case of the "transportation packing box with the slope for reagent exchange robot", packaging specifications were changed from wooden boxes to reinforced cardboard, reducing unpacking time by 50% and reducing CO2 emissions generated from the procurement of materials to the disposal of packaging boxes by 90%.

| Award-winning case / Award titles | Main effect |

|---|---|

| Technical Packaging Award / Conversion of Elevator Component Wooden Boxes to Cardboard |

|

| Large and Heavy Item Packaging Category Award / Transport Packaging Box with Ramp for Reagent Exchange Robots |

|

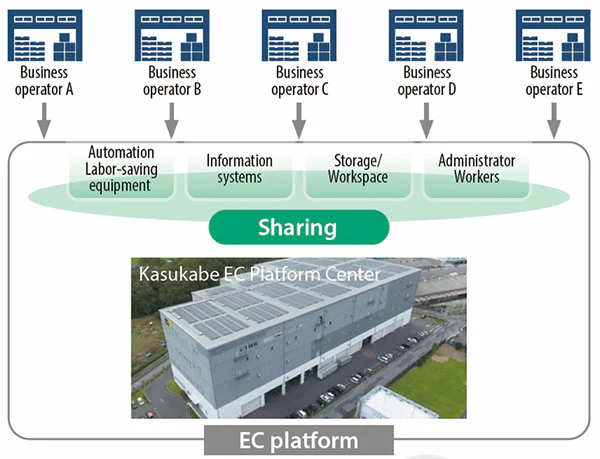

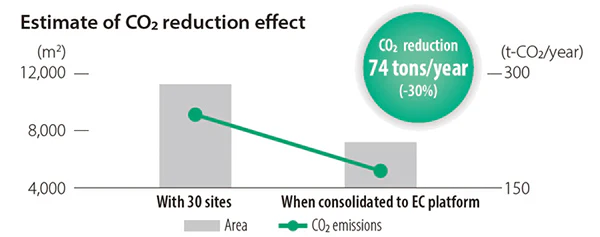

Operation of shared automated warehouse for EC logistics

We launched an EC platform center engaging in logistics services for EC operators in 2019. This center has achieved long hour operations, including at night, with standardized operation and automated equipment, allowing us to carry out logistics operations of multiple EC operators with one platform and to improve logistics efficiency and reduce environmental load by sharing facilities and equipment.

When comparing with the CO2 emissions of the traditional logistics which uses multiple sites for each EC operator, although there are some increasing factors including a rise in electricity consumption due to expanded use of labor-saving and automated equipment, if we consolidate sites of up to 30 operators to the EC platform, we can expect an approximately 30% reduction in emission in one year through improvement of energy efficiency.

This initiative was recognized, and we received "Advanced Technology Award" in the "22nd Logistics Environment Awards (2021)."

Support for decarbonization of customers' businesses through SCDOS

-Support customers' decarbonization by providing SCDOS "EcoLogiPortal"-

As part of "SCDOS," our DX service to support optimization of customers' supply chain, we offer "CO2 emission visualization function" from FY2021.

This service enables customers to accurately measure and visualize CO2 emissions and reduction in the supply chain by centrally managing and monitoring their various data, which has received conformity assessment by a third-party organization.

In FY2023, we submitted more proposals than our initial goal, and we are also working to introduce and deploy our services to overseas customers. Through this, we supported the visualization and reduction of CO2 emissions in the logistics domain for customers in Japan as well as overseas.

Logistics services adapted to a recycling-oriented society

We support businesses that respond to consumer orientation changes of from buying to renting and from owning to using through "Recovice," a logistics service for customers who provide usage and experience types of services such as rentals, subscriptions, and sharing. Through this, we are contributing to the development of a recycling-oriented society.

Improve Eco-Mind Level and Enhance Eco-Management System

The Group is working to raise the environmental awareness of its employees through environmental education and other means. In FY2019, we reviewed the existing environmental management system to track the actual data more accurately and conduct monitoring activities. In addition, we investigate the environmental load of our business establishments and important environmental laws and regulations overseas, and strive to manage the environmental load and ensure legal compliance.

Raising environmental awareness

Environmental e-learning

Every year, e-learning is provided mainly for domestic employees, in order to facilitate employees' understanding of global warming, resources recycling and ecosystem integrity.

In addition, e-learning for the Group Code of Conduct contains programs about environment to disseminate the importance of environment as business ethics to employees.

Utilization of management system (domestic)

Management systems currently in use

| System name | Introduction purpose | Number of sites/ (in parentheses: % of total sites) as of March, 2024 |

|---|---|---|

| Industrial waste management system |

Manifest management under the Waste Management and Public Cleansing Act Improving the management level of waste and other emissions through complete renewal that emphasizes operability and efficiency |

250sites(100) |

| Environmental load research system |

Survey of energy consumption such as electricity and fuel under the Act on Rational Use of Energy, etc. Improvement of accuracy of environmental load data by improvement of input/aggregation operations |

374sites(100) |

| Vehicle management system |

Management of vehicle fuel consumption, mileage, registration information under the Act on Rational Use of Energy, the Law Concerning Special Measures for Total Emission Reduction of Nitrogen Oxides and Particulate Matter from Automobiles in Specified Areas, etc. Improvement of vehicle management levels by improving operability and functionalities |

435sites(100) |

Boosting of the management level through continuing training and conferences

We are working to improve the level of environmental management through a variety of training and meetings.

Training aimed at maintaining and improving the level of environmental management

We strive to maintain and improve the level of environmental management by continuously conducting environmental training.

Maintaining and increasing of waste recycling rate

Holding environmental promotion conference

We share environmental information in Japan and overseas to improve environmental awareness and the management level.

| Number of environment conferences held (FY2023) |

Domestic: environmental promotion conference 2 times |

|---|---|

| Oversea: environmental officers meeting 2 times |

Performance of internal environmental audit

We perform internal audit to prevent or promptly correct violations of the environmental compliance and improve the management level.

| Number of sites audited (domestic) (FY2023) |

129 sites |

|---|

Third-party certification Initiatives

We seek third-party certification and the Sustainability Promotion Department has acquired the "Eco Stage" certification.

From FY2017, we have upgraded the certification level to "Eco Stage II" which is equivalent to ISO14001, and are rolling out an environmental management system across the entire company and otherwise working to improve the level of environmental management at the Group as a whole.

In FY2019, LOGISTEED Central Japan, Co., Ltd., our group company, independently acquired "Eco Stage II Certification," and has been continuously renewing it. In addition, as of April 2023, we have earned "Green Management Certification" at 11 of our truck transport sites and 7 of our warehouses.Building on these management systems, we are committed to ongoing reduction of environmental load.

Scope: The Company, domestic group companies

| Scope of Eco Stage 2 |

|---|

| 334 sites (All sites in Japan as of the end of March 2024) |

Eco Stage II Certification

Green Management Certification

Third-party certification on CO2 emissions data

For greenhouse gas (GHG) emissions* in FY2021, the Group acquired a third-party certification based on ISO14064-3:2019 through an assessment by a certification body LRQA Limited in FY2022. We will continue to secure the reliability of our calculated data by obtaining a third-party certification and also work to expand the scope to "Scope 3."

*Scope: CO2 emissions in scope 1 and scope 2 (domestic)

Relating to GHG Emissions for the fiscal Year 2022 (PDF format, 528kBytes)

Consideration the use of internal carbon pricing (ICP)

In order to promote decarbonization initiatives, we are considering the use of ICP in investment decisions. In FY2022, we set ICP at 10,000 yen/t-CO2 and studied how to operate it. In the future, we will establish a system for ICP-based investment decisions and make it widely known within the Company.

Strengthening cooperation with overseas group companies

In order to reduce the environmental load of the entire Group, including overseas companies, we are working to strengthen cooperation with overseas locations. In FY2023, overseas subsidiaries also established environmental action plans tailored to the specific circumstances of each country.

Initiatives to set CO2 emission reduction targets throughout the supply chain

To set CO2 emission (Scope 3) reduction targets throughout the supply chain, we have been conducting fact-finding surveys of CO2 emissions in overseas group companies and building a system to calculate and visualize emissions with higher accuracy since FY2022. In FY2023, we worked on selecting and preparing for the implementation of a CO2 emissions visualization system our overseas business.

Environmental compliance

Ensuring compliance in overseas offices

We identify important environmental laws and regulations related to "Transport and Warehouse Business" in overseas sites and conduct research on their outline in 29 countries and regions from FY2017 to ensure proper operation management in each site. In FY2021, we completed research on Germany and France, bringing the total number of researched countries and regions to 20.

Non-compliance with environmental laws and regulations

The number of non-compliance with environmental laws and regulations at our company in FY2023 was 0.

Promote Symbiosis with Nature and Environmental Communications

The Group promotes resource recycling initiatives with consciousness of nature conservation, environmental communication such as dissemination of environmental information within the Company and environmental activities at each site, and strengthens disclosure of environmental information externally.

Boosting communication on the environment

We hold "Green Action Workshop," an interactive employee activity that incorporates the perspective of reducing environmental load into VC activities since FY2021, and also hold "Environment Prize in VC Award" to recognize innovative initiatives as environmental communication. In FY2022, we held "Digital Dialogue Session" where the management and employees discussed their ideas and views on decarbonization, etc., and also held workshops to visualize the environmental action plan.

Posting education articles in the company magazine

We publish a newsletter for employees that includes general knowledge about the environment, examples of initiatives within the Group, and topical information in order to raise employees' environmental awareness and urge active participation in environmental initiatives. In FY2023, we published content such as easy-to-understand information on points for further energy-saving in warehouses and examples of modal shifts that can significantly reduce CO2 emissions.

Establishment of clean-up activities/light-down -environment month

As environmental communication activities, we have implemented clean-up activities and light down around our sites.

In order to promote the understanding of employees regarding the environment, in line with World Environment Day on June 5, which is set by the United Nations, since FY2015 we have designated June, including this day, as the Group Environment Month, and has been promoting environmental beautification activities and social contribution activities around the common theme of "contribution to local community."

Clean-up activities around sites

Tree-planting establishment around sites(Before)

Tree-planting establishment around sites(After)

Collection and donation of used clothing

Eco cap activity

Green curtain installation

Overseas environmental activities

At our group company, Manila International Freight Forwarders, 33 of our employees participated as volunteers in tree-planting activities in February and July 2023. This initiative is aimed at protecting the La Mesa Watershed in Quezon City, Philippines, a tropical rainforest and one of the region's water sources. This effort not only involves planting and nurturing trees but also aims to strengthen ties with the local community and foster a sense of responsibility toward the planet. We will continue to actively engage in such initiatives going forward.

Promotion of resource recycling/Protection of forest timber resources

Maintaining and increasing of recycling rate

In order to recycle the waste generated in our business activities as much as possible, we have been actively promoting the implementation of waste emission control measures and efforts to reduce the amount of landfill disposal in the Group overall, and striving to maintain and improve the recycling rate.

Scope: The Company, domestic group companies

| Recycling rate (FY2023) | Target | Result |

|---|---|---|

| 99% | 99% |

Promoting green purchasing

We try to promote Green Purchasing when purchasing office supplies by choosing stationery made from recycled materials, recycled paper, etc.

Scope: The Company, domestic group companies

| Green purchasing rate*(FY2023) | Target | Result |

|---|---|---|

| 85% | 78.6% |

*Green purchasing rate: the ratio of office supplies purchased at the e-sourcing MALL (an electronic purchasing system) that are environmentally-friendly products.

Reduction of water consumption

Water used for car washing and dust control is also a limited resource, therefore we have been working to reduce the amount of water consumption by using this efficiently.

Scope: The Company, domestic group companies

| Reduction of water consumption intensity per floor space (FY2023) | Target | Result |

|---|---|---|

| YoY -1% | YoY ±0% |

Reduction of copy paper

To protect forest resources, we have been working to reduce the amount of copy paper used by promoting paperless meeting materials.

Scope: The Company, domestic group companies

| Rate of reducing copy paper consumption (FY2023) | Target | Result |

|---|---|---|

| YoY -1% | YoY +4.4% |

Scope: The Company, domestic group companies

| Total amount of copy paper used (thousand of sheets) converted to A4 size |

FY2021 | FY2022 | FY2023 |

|---|---|---|---|

| 114,640 | 113,866 | 118,826 |

Environmental disclosure

We participated in (responded to) the CDP*1 Questionnaire for the first time in 2020, receiving a high rating of A-, the leadership level, in the four consecutive years of 2020 and 2023 for our climate change initiatives and information disclosure. With regard to climate change-related issues, we have strengthened our management system, including at the board level, identified climate-related risks and opportunities from short-, medium-, and long-term perspectives, estimated the financial impact, and studied and implemented countermeasures according to the level of importance, and considered climate-related risks and opportunities as important issues in its business strategy. Those and it being transparent in setting medium-to-long-term environmental targets, taking actions for mitigation, and implementing measures gained it a high rating.

We are also preparing for the implementation of the declaration of CO2 reduction targets (setting of SBT*2) based on scientific evidence, and we have been working on "Environmental Accounting*3" in order to effectively promote its environmental efforts.

We also consider biodiversity and natural environment-related risks and opportunities to be important, and we will continue to deepen our consideration of items that are particularly dependent on and affected by the natural environment as we move forward with business activities.

Participation in Green Value Chain Platform by the Ministry of the Environment

As part of the ESG management initiatives, from FY2019 we have been a member of the Network for Promoting Decarbonized Management of the Green Value Chain Platform organized by the Ministry of the Environment and the Ministry of Economy, Trade and Industry, and we participate in regular study sessions.

Environment Data

Environmental protection investment and cost (FY2023)

(Millions of yen)

| Category | Investment | Cost |

|---|---|---|

| 1. Cost within the our business activities | 566.2 | 3,225.0 |

| 2. Upstream and downstream costs | 0 | 0 |

| 3. Managerial activity costs | 0 | 510.1 |

| 4. R&D costs | 0 | 0 |

| 5. Social efforts costs | 0 | 6.1 |

| 6. Other costs | 0 | 0 |

| Total | 566.2 | 3,741.2 |

Aggregation method

Energy consumption (crude oil equivalent)

Unit: kl/(inside parenthesis): composition ratio

| Electricity | Gas oil | Gasoline | Other | Total* | |

|---|---|---|---|---|---|

| FY2023 | 33,206(67.9) | 13,482(27.6) | 665(1.4) | 1,583(3.1) | 48,937(100) |

| FY2022 | 39,393(72.5) | 12,662(23.3) | 717(1.3) | 1,590(2.9) | 54,362(100) |

| FY2021 | 42,330(73.9) | 12,755(22.3) | 791(1.4) | 1,379(2.4) | 57,255(100) |

| FY2020 | 44,461(74.0) | 13,405(22.3) | 866(1.4) | 1,320(2.3) | 60,052(100) |

| FY2019 | 45,870(73.8) | 13,567(21.8) | 1,150(1.8) | 1,587(2.6) | 62,174(100) |

Scope: The Company, domestic group companies

*Due to rounding to the nearest whole number, totals and breakdown totals may not match

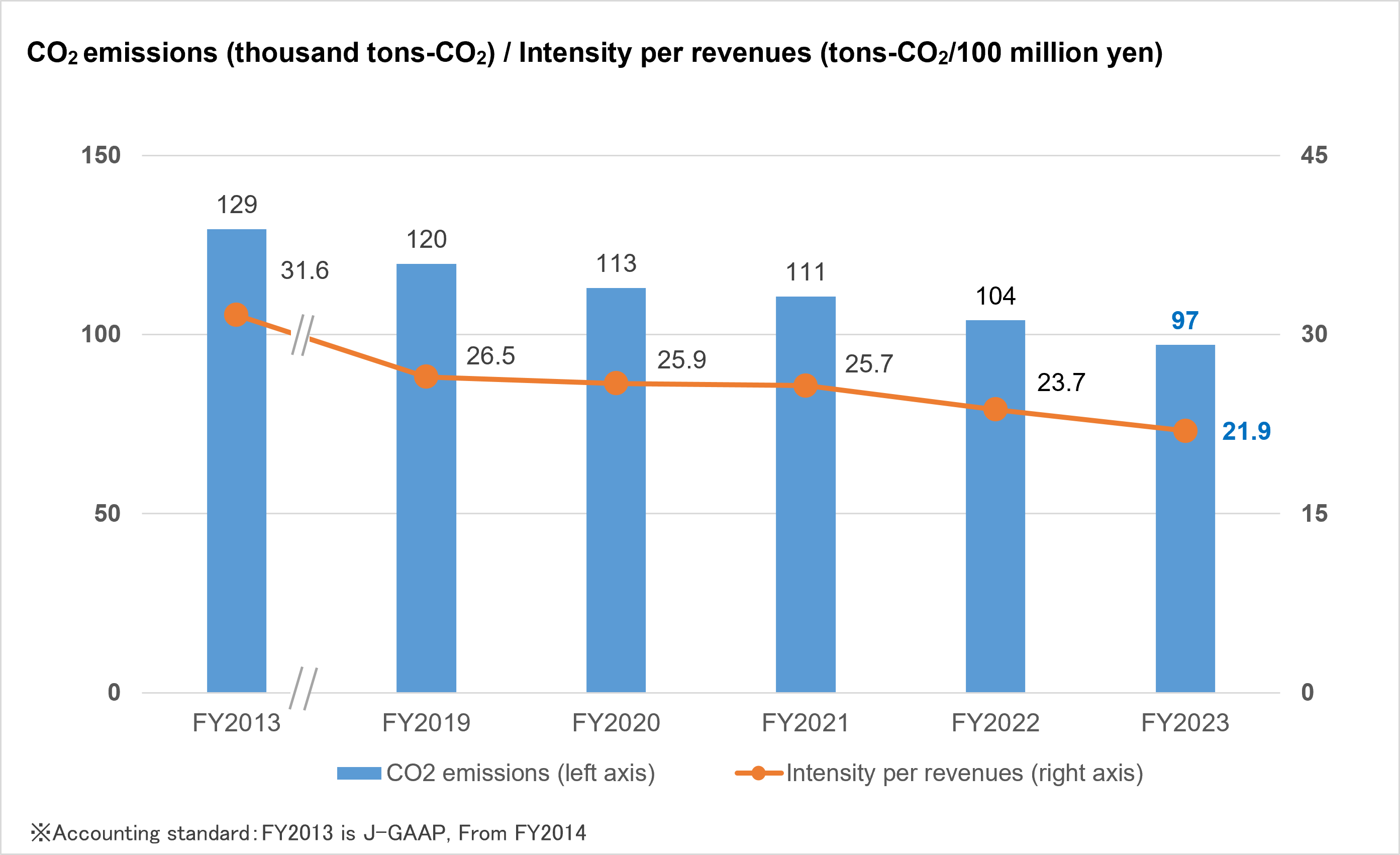

CO2 emissions and intensity per revenues

*CO2 emissions are total of Scope 1 and 2

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|---|

| Scope 1 (t-CO2) | 42,207 | 40,669 | 40,519 | 40,641 | 41,267 |

| Scope 2 (t-CO2) | 77,546 | 72,326 | 70,097 | 63,316 | 55,823 |

| Scope 1⁺2 (t-CO2) | 119,753 | 112,995 | 110,616 | 103,957 | 97,091 |

| Intensity per revenues (tons-CO2 / 100 million yen) | 26.5 | 25.9 | 25.7 | 23.7 | 21.9 |

Third-party certification on CO2 emissions data

Scope: The Company, domestic group companies

*Due to rounding to the nearest whole number, totals and breakdown totals may not match

Scope 1 total emissions (FY2023)

Scope: The Company, domestic group companies

Global warming coefficient used: IPCC Fifth Assessment Report (AR5-100 year values)

| Greenhouse Gas | Scope 1 emissions (CO2 equivalent) |

|---|---|

| CO2 (ton) | 41,267 |

| CH4 (ton) | 0 |

| N2O (ton) | 0 |

| HFC (ton) | 0 |

| PFC (ton) | 0 |

| SF6 (ton) | 0 |

| NF3 (ton) | 0 |

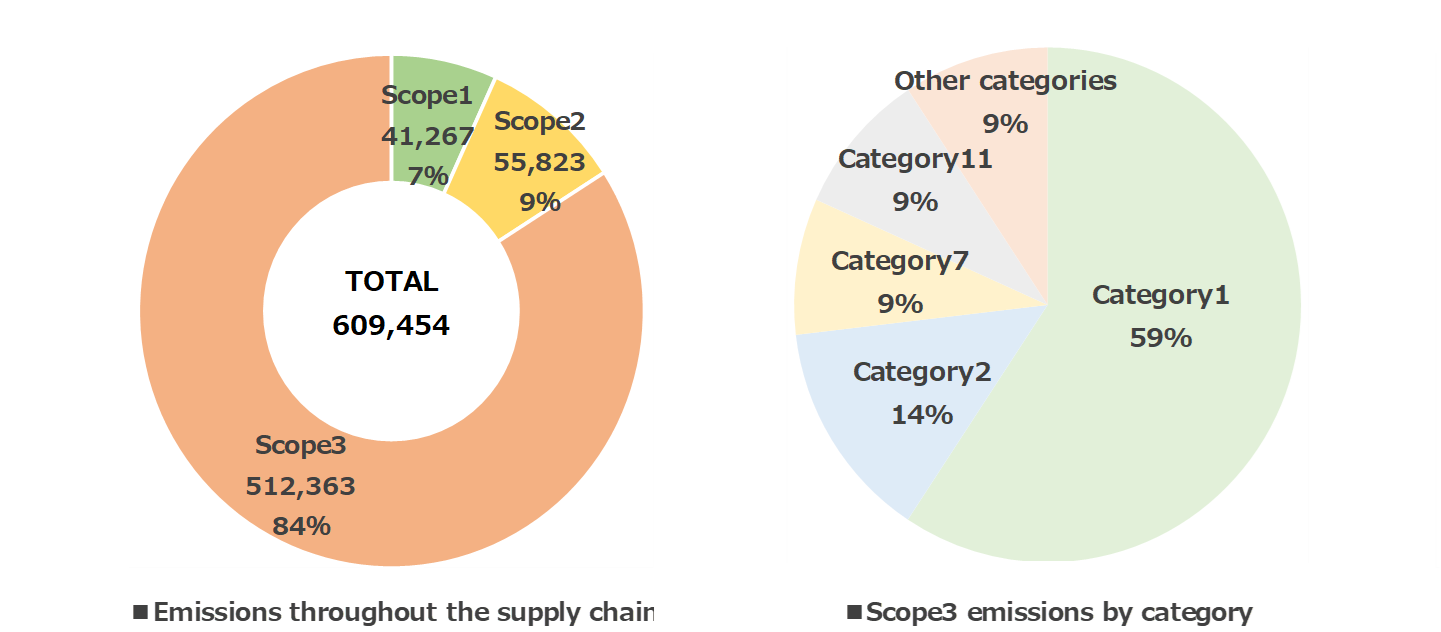

CO2 emissions throughout the supply chain (FY2023)

CO2 emissions data in Scope 3 (CO2 emissions rate by category)

| Category | Active data | Rate |

|---|---|---|

| 1 |

|

59.3% |

| 2 |

|

13.8% |

| 3 |

|

3.1% |

| 4 |

|

0.0% |

| 5 |

|

1.3% |

| 6 |

|

1.2% |

| 7 |

|

8.6% |

| 8 |

|

- |

| 9 |

|

- |

| 10 |

|

- |

| 11 |

|

9.0% |

| 12 |

|

3.2% |

| 13 |

|

0.4% |

| 14 |

|

- |

| 15 |

|

- |

Trend of CO2 emissions throughout the supply chain (Scope3)(t-CO2)

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 |

|---|---|---|---|---|

| 527,189 | 496,788 | 513,312 | 590,518 | 512,363 |

*The above is domestic emissions on a consolidated basis.

Emissions of hazardous waste

Scope: The Company, domestic group companies

| Hazardous waste | Emission | ||

|---|---|---|---|

| FY2021 | FY2022 | FY2023 | |

| PCB (ton) | 0.0 | 0.0 | 0.2 |

Environmental Data

The following is environmental data.