With Our Customers

In addition to fulfilling our role as a logistics company providing social infrastructure supporting industry and people's lives, we will contribute to the resolution of various environmental and social issues and the realization of a sustainable society through collaborative creation with customers beyond the logistics field.

- To Build Resilient, Sustainable Logistics Services

- To Evolve Resilient, Sustainable Logistics Services

- Promote DX

- Develop New Value through Collaborative Innovation

To Build Resilient, Sustainable Logistics Services

Storage and transportation/delivery conforming to GDP

We have enhanced medical DCs across the country and provide storage and shipping services specialized in pharmaceutical logistics.

In order to enhance intangible aspects of GDP*1, we are working to strengthen quality assurance system in the pharmaceutical logistics. For example, we set up an organization dedicated to promoting GDP, which is developing a quality management system for GDP management and also conducting verification experiments such as for the next-generation temperature sensor to monitor temperature during transportation. In FY2021, we provided our customers with low-cost GDP-compliant temperature mapping services at the advanced medical DC, including preparation of implementation plans and reports.

We also have a fuel procurement scheme and dedicated drivers familiar with characteristics, etc. of medicines as part of the BCP system to sustain supply chain in case of an emergency.

In FY2023, we introduced a temperature control system to strengthen the intangible aspects of temperature control, which is a requirement for GDP. The introduction of this system has enabled real-time temperature monitoring at our advanced pharmaceutical logistics center, and we are now able to respond immediately when an alarm is triggered. In addition, the temperature control system enables "centralized management of important record data", "permanent storage of temperature data," and "management on a highly secure and reliable platform", and we have also implemented computerized system validation support. Furthermore, in the "GDP Video Education" program, which was established with the aim of further strengthening quality control and operational capabilities, we have implemented an "intermediate level" in addition to the "basic level" from FY2023. Moreover, in order to improve the efficiency of GDP document and record management and strengthen data integrity, we have introduced a document and record management system (HITQUAA*2) with the same level of functionality as the manufacturing field to our main bases in Kanto and Kansai. Into the future, we will continue to develop and introduce standard systems for temperature management during transport in addition to temperature management in warehouses.

Overseas, LOGISTEED Hong Kong, Ltd. obtained CEIV Pharma pharmaceutical transportation quality certification at Hong Kong International Airport.

We will continue to contribute to maintaining high quality pharmaceutical logistics by working on proper management of increasingly complex distribution channels.

- *1: GDP (Good Distribution Practice): "Appropriate distribution standard for medical supply" to ensure strict quality control to prevent quality deterioration during transportation and storage.

- *2: "HITQUAA" is a registered trademark of Hitachi Industry & Control Solutions, Ltd.

Area of medical DCs: About 270,000 square meters (as of March 31, 2024)

Of these, standard equipment for distribution centers that conform to GDP

- Dock Shelters

- Temperature sensor calibration

- Whole building air conditioning system

- Emergency backup generators

- Alarm activation management

- Access security

GDP education program

| GDP promotion meeting (FY2023) | 6 times, 178 attendees in total |

|---|---|

| GDP video education (FY2023) | 9 times, 1,527 attendees in total |

Installing automated/labor-saving technology and equipment

The Group is promoting the implementation of automation and labor saving technologies at logistics sites, and introduction of equipment, in order to respond to social issues such as labor shortages, leading to a reduction in the burden on workers and establish a safe, secure and friendly workplace and a sustainable logistics management system.

Main equipment introduced in FY2023

Installed automated/labor-saving equipment, saving 100 FTE* per year compared to FY2022

- Rotary piece sorters

- Palletizer/Depalletizer

- Automated forklift

- Auto-Guiding AGV (Automated Guided Vehicle)

- Piece picking robot

*FTE (Full-Time Equivalent): A unit of the full-time work amount in an organization

Main equipment already installed

Rotary piece sorters

We are working to improve operational productivity by temporarily storing piece shipment items put in trays in rotary piece sorters and automatically discharging them in delivery destinations units. We have been promoting the installation since FY2018, and this is currently installed at five sites.

Medical DC (A)

Apparel DC (B)

Apparel DC (C)

Apparel DC (D)

Medical DC (E)

Automated forklift

Interoperability with mobile pallet racks, vertical conveyors, and automated warehouses to automate pallet cargo handling (warehousing/shipping) and transportation, including at night. We have been promoting the installation since FY2018, and this is currently installed at three sites.

Medical DC (E)

Daily Commodities DC (F)

Medical DC (G)

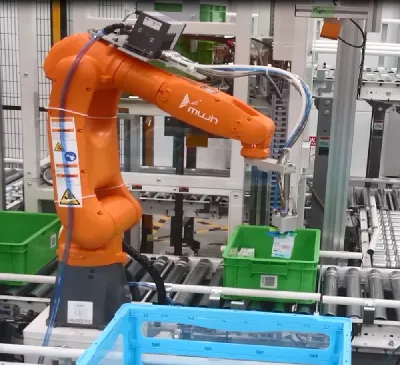

Piece picking robot

Promoting labor saving in simple work by replacing the manual picking and placing process with piece picking robots with specifications according to the product characteristics. We have been promoting the installation since FY2019, and this is introduced at three sites.

Apparel DC (C)

Medical DC (A)

Apparel DC (B)

Depalletizer/palletizer

Depalletizers and palletizers are used with products shipped by the case for loading and unloading between pallets and conveyor lines and for stacking products from conveyor lines onto cage carts, thereby reducing the amount of heavy-lifting work and achieving labor-saving operations. We have been promoting their introduction since FY2019, and they are introduced at ten sites.

Medical DC (E)

Consumer & Retail DC (H)

Consumer & Retail DC (I)

Consumer & Retail DC (J)

Medical DC (G)

Consumer & Retail DC (K)

Consumer & Retail DC (L)

Consumer & Retail DC (Q)

Consumer & Retail DC (R)

Consumer & Retail DC (W)

AGV (Automatic Guided Vehicle)

In addition to pallet transport and the like, these are utilized as shelf transport type picking and sorting systems for small goods to promote labor-saving in transport and picking/sorting operations. We have been promoting the introduction since FY2014, and these are currently introduced at eight sites.

Apparel DC (C)

Medical DC (M)

Shopping DC (N)

Daily Commodities DC (O)

Medical DC (G)

Consumer & Retail DC (R)

Consumer & Retail DC (U)

Apparel DC (V)

AMR (Autonomous Mobile Robot)

Utilizing picking assistant type AMRs in picking operations for small goods within warehouses reduces the distance walked by workers, leading to an increase in productivity. We have proceeded to implement these since FY2022, and have currently installed them in two sites.

Apparel DC (S)

Transportation equipment DC (X)

Introduction at overseas sites

We are promoting the introduction of automation and labor-saving equipment at our overseas sites as well, and in FY2023, we introduced SLAM guided pallet transfer AGVs at our Tianjin base in China.

Daily Commodities DC (O)

Daily Commodities DC (Y)

Promotion of transportation of social infrastructure-related equipment

-Transport and installation of platform screen doors at railway operators-

The installation of platform screen doors is an important issue for improving safety on station platforms, and work is being accelerated to reduce the number of accidents involving falls or contact with trains at station platforms and the resulting delays to trains. In the "First Basic Plan on Transport Policy" approved by Japan's Cabinet in 2015, the government indicated its policy of prioritizing the installation of platform screen doors at stations with an average daily passenger volume of 100,000 or more by utilizing a subsidy system for their installation, thereby promoting the installation of platform screen doors. In addition, a new target year of FY2025 has been set for barrier-free access, and further improvements are planned for the future.

The Group has a wealth of experienced engineers and a wide range of equipment, and we have been involved in the consolidated logistics of various products, from transportation to installation work. Using this experience and track record, we have completed the installation of platform screen doors at many station platforms without any accidents up to 2023.

We will continue to support our customers' business activities and the spread of platform screen doors by providing total solutions for the safe and reliable installation of important products, and we will strive to improve safety for users and contribute to the creation of a prosperous society.

Unloading

Moving into the station

Loading onto cars

Securing products in train cabin

Installation at platform

Completed platform screen door

Heavy Transport and Relocation

To Evolve Resilient, Sustainable Logistics Services

SSCV (Smart & Safety Connected Vehicle) transport digital platform

"SSCV" is a transport digital platform that updates transport business through technology and open collaborative creation, and it consists of the following three solutions.

- Providing transport operators with legal compliance and efficient work methods "SSCV-Smart"

- Stay close to drivers "SSCV-Safety"

- Managing trucks easier "SSCV-Vehicle"

"SSCV" will build new business models contributing to the resolution of various social issues with services from ideas originating at the worksite that only a logistics company can provide and the utilization of big data obtained from services, connecting transport and society for a better future and contributing to the realization of a sustainable society.

SSCV₋Safety (Safety Operation Management Solution)

SSCV-Safety features and functions

"SSCV-Safety" is a solution with which we aim for "zero accidents," developed as a result of our long-standing commitment to accident prevention and safety as a logistics company. The health status measurement function for drivers and the dashboard function for managers work in tandem to detect in real time near-misses that could lead to accidents.

In addition, the following functional enhancements were implemented in FY2023.

- Digital labor management:

- Automatically linked with digital tachographs to identify and visualize drivers' overtime hours

- IT roll call:

- Enables roll call to be carried out remotely, rather than face-to-face, using devices such as PCs and smartphones (This can be implemented at G-Mark certified offices, etc.)

- Driving risk assessment:

- The fatigue level of drivers is assessed based on the information on their physical condition measured on a daily basis, and the driving manager can be notified that the driving risk is increasing.

In the future, we will work on expanding the functions of the system with the aim of strengthening compliance and improving the efficiency of driving management work in response to further legal regulation.

| Status | Functions | Features | |

|---|---|---|---|

| Before driving | Predict |

|

Driver "fatigue" and "stress" that can lead to distracted driving are visualized, accident risk is predicted in advance using a unique algorithm. |

| While driving | Watch over |

|

Dangerous situations (driving, fatigue level) are detected and drivers are notified on the spot, and managers can monitor the situation to catch near-misses in real time, rather than after the fact. |

| After driving | Review |

|

Risk of accidents, which was previously determined by experience and intuition, is predicted and environment where drivers can be trained and evaluated based on facts and data is provided, thereby supporting the creation of a system to prevent accidents before they occur. |

SSCV-Safety value offers/effectiveness

- Prevention of accidents caused by health

- Watching over drivers during operation

- Thorough labor management of drivers

- Fairly appraising excellent drivers

- Skills guidance tailored to the driver

- Coaching on daily driving conditions

Introduction results and effects

In FY2019, we began full-scale introduction of "SSCV-Safety" to domestic commercial trucks and personal vehicles, and by FY2021 the system has been installed on all of the company's approximately 2,200 vehicles. Since introducing the system, we have maintained zero vehicle accidents caused by distracted driving, thereby minimizing the occurrence of accidents. Starting in 2021, we have been offering the service to other transport companies outside the Group, and we are working to further spread the use of "SSCV-Safety".

"SSCV-Safety" is certified as "TDBC Certified Solution" by Transportation Digital Business Conference (TDBC) and is used in initiatives to solve social issues such as research projects by the Ministry of Health, Labour and Welfare and verification experiments by the Ministry of Land, Infrastructure, Transport and Tourism.

In FY2023, we received the Good Design Award from the Japan Institute of Design Promotion.

Number of vehicles installed with SSCV-Safety (as of March 31, 2024: cumulative)

| Type | No. of vehicles |

|---|---|

| Our group companies | 2,349 |

| Partner companies | 557 |

| External transport operators | 160 |

| Total | 3,066 |

SSCV₋Smart (Transportation Business Support Solution)

The truck transport industry is made up mostly of small and medium-sized businesses, and many of them still conduct operations using telephone, fax machine, and paper documents. "SSCV-Smart", developed by us, is a transport operations support solution for cargo owners and transporters that supports business efficiency and legal compliance on both sides.

Basic functions of SSCV-Smart

"SSCV-Smart" is an online system that connects cargo owners and transporters via the Internet. It supports business efficiency and legal compliance, as the system allows for centralized management of all processes from acquiring transportation projects to vehicle assignment, issuing driving instructions, and billing, in addition to supporting saving of electronic books and the invoice system.

Installation of SSCV-Smart (as of March 31, 2024: cumulative)

| No. of companies that installed SSCV-Smart | 751 |

|---|

SSCV-Vehicle (Vehicle Management Solution)

Vehicle management is complicated and involves a wide range of tasks such as inspection, maintenance, and insurance renewal. In addition, compliance with laws and regulations is required, and inadequate management can lead to major risks. "SSCV-Vehicle" is a new solution for vehicle management that combines the unique perspective of a logistics company with technology.

Basic functions of SSCV-Vehicle

"SSCV-Vehicle" centralizes and supports the individual management operations from vehicle procurement to purchase. Currently, we are developing preventive diagnosis functions, such as remote diagnosis and failure prediction alerts utilizing IoT technology and big data.

Installation of SSCV-Vehicle (as of March 31, 2024: cumulative)

| No. of vehicles installed with SSCV-Vehicle* | 3,249 |

|---|

*The total number of trucks, business vehicles and forklifts owned by group companies in Japan that have introduced SSCV₋Vehicle

Improve the Resilience of Transport Business (including addressing the transport capacity shortage in the 2024 issue)

Addressing the transport capacity shortage across society, including the 2024 issue*, requires urgent measures such as shortening total working hours of drivers and strengthening transportation capacity to compensate for the shortage of drivers. The LOGISTEED Group is working on promotion of modal shifts, labor-saving/capacity increase/short-haul transport by introducing double-trailer trucks, and reduction in waiting time for loading/unloading through development and introduction of a loading dock booking management system. We are also working to improve transport efficiency by utilizing DX solutions such as SSCV. As a result of these initiatives, the number of violations of labor standards by the LOGISTEED Group's truck drivers was zero in FY2023.

* The 2024 issue: Various problems arising from the limitations on drivers' overtime work imposed by the Work Style Reform Act, which has been applicable starting in 2024.

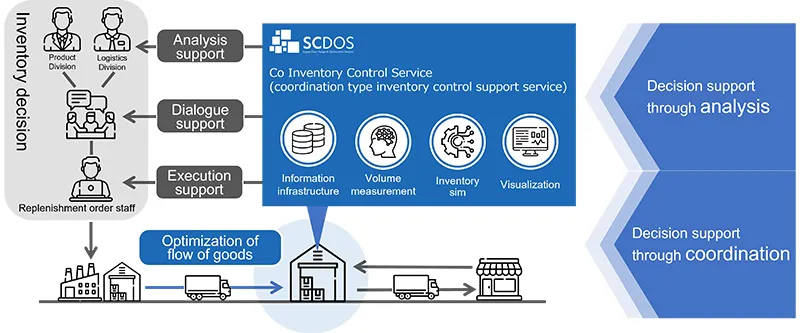

Expanding functions of SCDOS

-SCDOS_Co Inventory Control Service (coordination type inventory control support service)-

Maintaining appropriate inventories helps companies reduce wasteful storage costs, maintain product quality, and ensure a stable supply of products, but timely inventory resupply decisions are essential to achieving this goal. We aim to contribute to customers' logistics optimization by supporting the execution of inventory replenishment orders through inventory analysis and evaluation using a wide range of data generated in the logistics process along with forecasting technology. In addition to implementing the coordination type inventory control support service in FY2023, we began providing consulting services to optimize the inventory optimization process in the supply chain to multiple customers in response to customer requests.

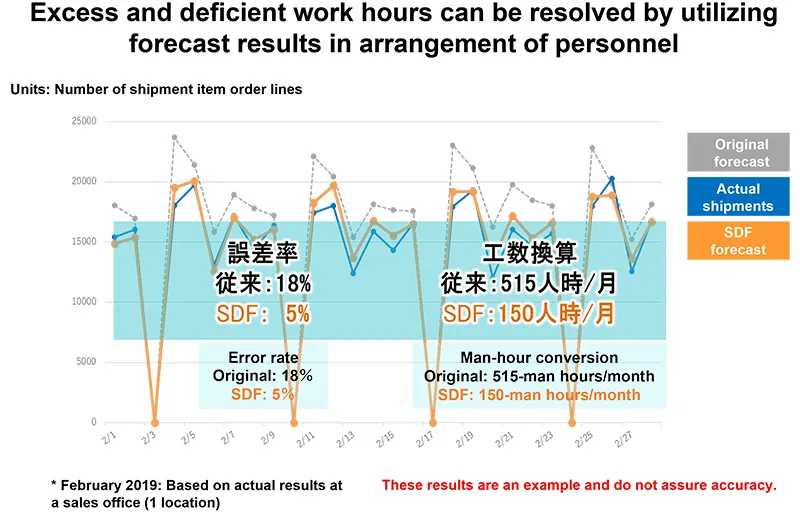

Expanding functions of SCDOS -volume forecasting tool-

Utilizing knowledge obtained in logistics operations to date and AI-based high-precision predictive technology, we are proceeding with the development of the SDF (Smart Demand Forecast) tool and expansion of functions enabling forecasting of future excesses and shortfalls of goods volume and workers. In FY2023, we strengthened linkage with the SCDOS supply chain visualization and analysis service and promoted general-purpose development of a demand forecasting function. As a result, we were able to provide demand forecasting tools to more customers. It is now possible to identify the transition of forecast good quantities based on seasonally busy days and future sales, and we will promote support for the formulation of logistics plans such as annual inventory and delivery volumes.

Utilization image

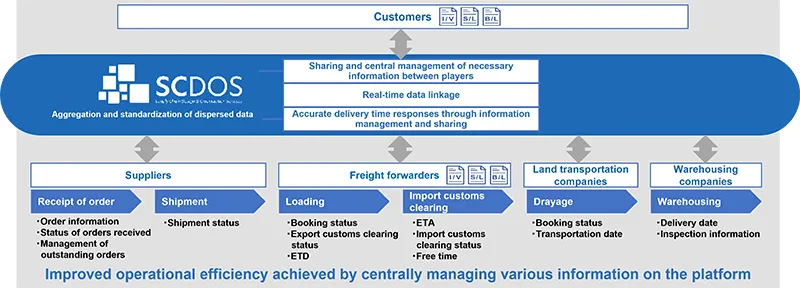

Expanding functions of SCDOS -SCLINK+(Service to improve efficiency of trade operations)-

Many customers have felt the limitations of improving efficiency through data tracking using spreadsheet software in import procurement operations. In this context, the Company provides "SCLINK+" for improving the efficiency of operations though platform-based management of data previously managed separately. Introducing this platform will visualize the number of orders and transportation status, enabling the reduction of manhours spent on inquires among the players in the supply chain and accurate responses on delivery time, leading to improvement of efficiency of operations.

Expanding functions of SCDOS -EcoLogiPortal (CO₂ emission visualization solution)-

As part of "SCDOS," our DX service to support optimization of customers' supply chain, we offer "CO₂ emission visualization function" from FY2021. This service enables customers to accurately measure and visualize CO₂ emissions and reduction in the supply chain by centrally managing and monitoring their various data, which has received conformity assessment by a third-party organization. In FY2023, we made more proposals than we originally planned and supported the visualization and reduction of CO₂ emissions from logistics domains of multiple customers in domestic and overseas.

- LOGISTEED Receives Special Award at the 25th Logistics Environment Awards

- Receives Conformity Assessment Results for Our SCDOS CO₂ Emissions Visualization Solution(August 2, 2022)

Promote DX

The Group is promoting DX by accelerating the digitalization, visualization and standardization of a variety of data arising in logistics sites, as labor shortages and long working hours become issues in the logistics industry.

Establish a digital platform to create innovation through DX

To create new values and innovation by promoting DX, we are working to develop and establish a company-wide digital platform for both business and management systems. We completed renewal of the core management system for domestic group companies in FY2022, enabling us to provide innovative digital services and promote data-driven management through linkage of the digital management platform and the digital business platform. In FY2023, we launched a pilot version of our core management system at our Group companies in Asia as a foothold for global expansion.

Execute logistics service reform projects utilizing a digital business platform

We are engaged in the transformation of logistics services through the utilization of digital business infrastructure to increase efficiency of business operations and improve productivity through DX. Digital business infrastructure is a digital platform for realizing logistics DX, and aggregates and standardizes a variety of digital data obtained day to day in the warehousing domain in the Group. Utilizing this digital business infrastructure, by FY2022, we completed over "60 logistics transformation projects" that was the target for FY2024. From FY2023 onwards, we are working to incorporate our accumulated knowledge into proposals for our customers, aiming to promote efficient and cost-effective logistics solutions.

Automation and labor saving in logistics centers and warehouses, and transformation of warehouse operations through DX

The Group is actively engaged in not only the promotion of labor saving in logistics centers, but also in improving efficiency and standardizing warehouse operations through DX to resolve social issues such as logistics delays/stagnation and rising logistics costs caused by labor shortages.

Implement Resource Control System (RCS: an integrated control system for equipment and people)

In the LOGISTEED Group, we are working to optimize the key resources of "equipment" and "people" in warehouse operations through RCS, aiming to enhance the overall throughput of the warehouse. RCS deploys solutions for both equipment management (RCS-Automation) and people management (RCS-Workforce), and we are also looking at the possibility of linking these two solutions in the future.

Equipment management (RCS-Automation)

Automation and labor-saving measures are inevitable if we are to be prepared for future labor shortages. In addition, it is anticipated that various equipment and robots will be introduced in logistics sites in the future, and there will be a need for task coordination between multiple equipment and robots. RCS-Automation supports the improvement of overall worksite throughput by controlling multiple equipment without relying on manufacturers, based on such needs. Even in controlling individual equipment, it is possible to add functions that are not available in the manufacturer's system using the control system developed by LOGISTEED independently, without relying on the manufacturer's control system, and to deploy our control know-how.

People management (RCS-Workforce)

We digitalize tasks that were previously dependent on individual workers, which helps eliminate reliance on specific individuals and promotes paperless operations, thus reducing administrative management burdens. Moreover, efforts to standardize worksite operations will enable business processes to be put in place, and it will become possible to compare and verify productivity per cargo owner. Additionally, based on visualized operational status, we can pre-allocate workers to their work areas, adjust allocations on the day, and make placement adjustments according to cut times.

Acquisition of Patent for "Resource Control System (RCS)" to Achieve Highly Automated Command Functions in Logistics Center (August 2, 2021) HTS received both "the 28th Japan MH Grand Prize (Excellence Award)" and "Logistics Award 2022 (Semi Grand Prize)"

Example of RCS installation -labor saving in logistics centers and Transformation of Warehouse Operations Through DX-

Implementing RCS in the household goods logistics center (Osaka) opened in FY2022 has enabled us to perform integrated control of automated facilities reflecting the Company's proprietary warehouse operation knowhow, and we have achieved efficient automation and labor saving in work processes from the receipt of products in single and case packing modes to sorting by destination. In FY2023, we introduced a similar system at a DC for sporting goods (in Tochigi Prefecture), and we are promoting automation and labor saving. Furthermore, the implementation of RCS has enabled swift processing of warehouse operations such as personnel assignment planning, shift planning and work process planning in warehouses that had previously relied on the knowledge of managers. The implementation of the DX solution called RCS has resulted in real-time budget and results management of facilities and personnel and the improvement of efficiency and standardization of resource control.

Online shopping DC (N)

Medical DC (G)

Consumer & Retail DC (P)

Reconstructuring of warehouse management system -enhance functions of a new WMS-PF ONEsLOGI-

We are working to standardize Warehouse Management System (WMS) to expand value we provide to our customers. We used to customize WMS by business type or customer. Now, in order to expedite and sophisticate our proposals on and provision of services to customers, we have reconstructed "ONEsLOGI, a new WMS-PF (standardized warehouse management system)" equipped with the Group's expertise on the warehouse domain as well as those acquired through the 3PL business over the years and all logistics-related functions as a standard solution. In FY2023, we achieved a conformance rate greater than our target.

| Conformance rate of ONEsLOGI new WMS-Platform to logistics operations(FY2023) | Target | Result |

|---|---|---|

| 90% | 94% |

Promotion of patent applications and acquisition of rights in DX field

We generally file patent applications for technologies and expertise that are important management resources to promote collaboration and innovation as business-related inventions, and most of such applications in recent years are DX-related. We will capture and visualize technologies and expertise as intangible assets to further create and utilize values.

|

Ratio of DX-related patent applications to total applications (as of March,31 2024, cumulative) |

8 cases |

|---|---|

| 67% |

Develop human resources with DX skills

In addition to enhancing DX training to secure DX personnel to handle the creation of new businesses utilizing IT and DX, we are developing data scientists for discovering and resolving customers' supply chain issues based on data.

Develope human resources with DX skills (With Our Employees)

|

Number of attendees of data scientist training course (as of March 31, 2024, cumulative) |

133 |

|---|

Develop New Value through Collaborative Innovation

Creation of cyclical logistics -Recovice-

"Recovice" developed to respond to consumption styles changing from ownership to use and experience is a service supporting subscription services of e-commerce operators through individual item management using RFID* tags and a cloud-based system.

As the fashion industry faces environmental issues such as mass consumption and disposal of apparel, this "Recovice" not only contributes to the realization of cyclical logistics supporting sharing, subscription and rental services, but also leads to "extension of product life" and circular economy through appropriate cargo handling.

*RFID (Radio Frequency Identification): Contactless automatic recognition technology that reads information via radio waves

Toward the realization of safe and sustainable logistics - use SSCV data to solve social issues -

We are seeking effective ways to use big data obtained from SSCV services and its new value in order to realize "smart and safe logistics." In a data utilization contest organized by collaborative innovation partner DAIWA HOUSE INDUSTRY CO., LTD. for solving issues related to the expected shortage of truck drivers when overtime is capped in 2024, we received a variety of ideas, including those on the use of a generative AI to automatically generate feedback comments for drivers based on data obtained from SSCV-Safety. Going forward, we will continue to utilize ideas submitted and data obtained from SSCV to create new businesses and solve social issues through collaborative innovation with partners beyond the industry.