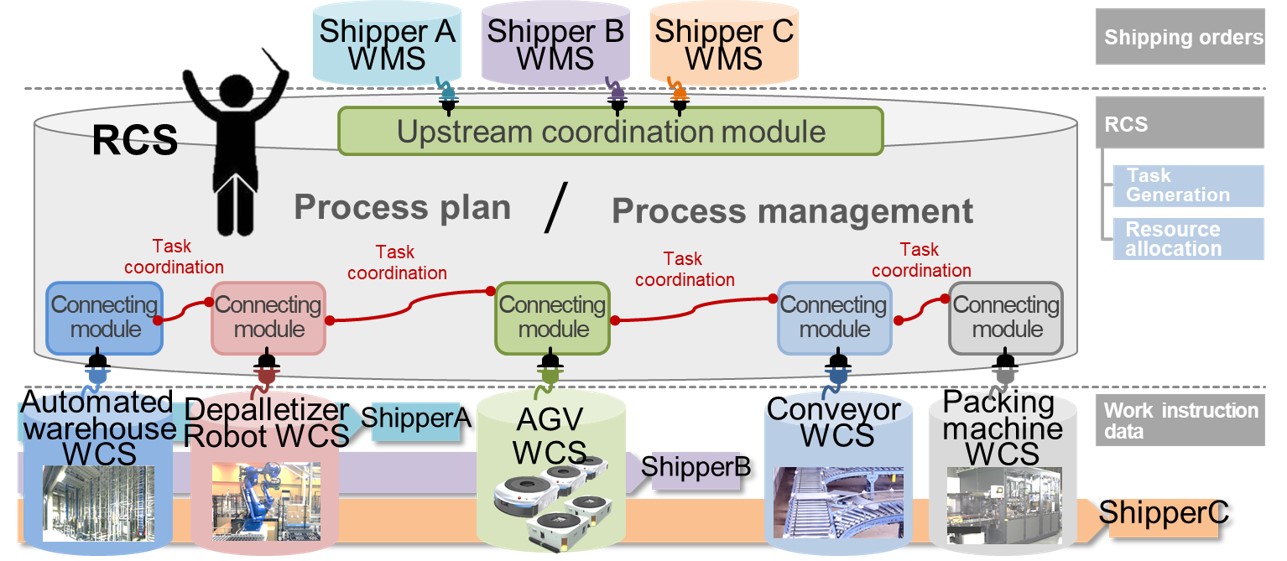

(1) Work instruction data for each process is generated by the function to create a process plan which added data of workload, work network, productivity of each process, overall resources (including personnel) with restrictions, priorities, and smoothing method, etc., and Task Generation, a function which efficiently groups receive/shipment information from multiple Warehouse Management System (WMS).

(2) t collects information on operation results of each material handling equipment, provides feedback to the process plan, and repeats scheduling to actively create an optimal process management plan.