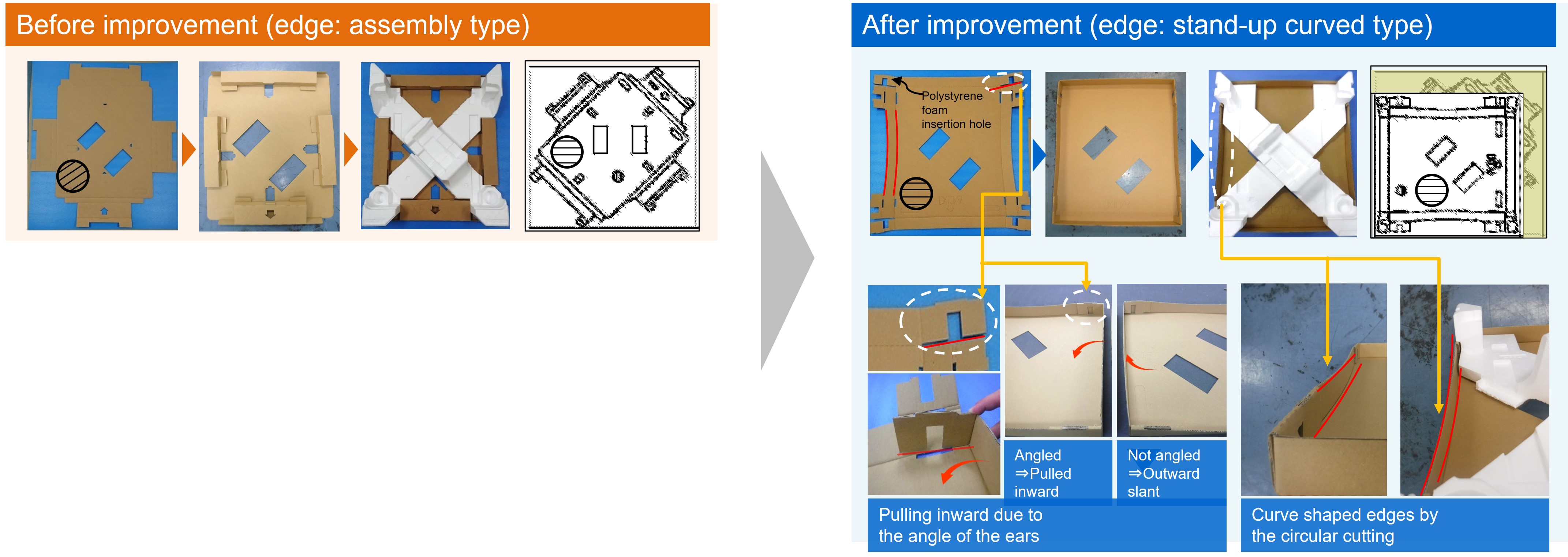

Until now, the under-tray of the packaging for washing machines required time-consuming assembly. In developing the packaging for a new washing machine, we tried to reduce the required time by improving the structure of the tray from an assembly type to a stand-up type. But when the ruled line※ was straight, the stand-up part rebounded outward and the tray would deform, making it difficult to cover the product with an outer box.

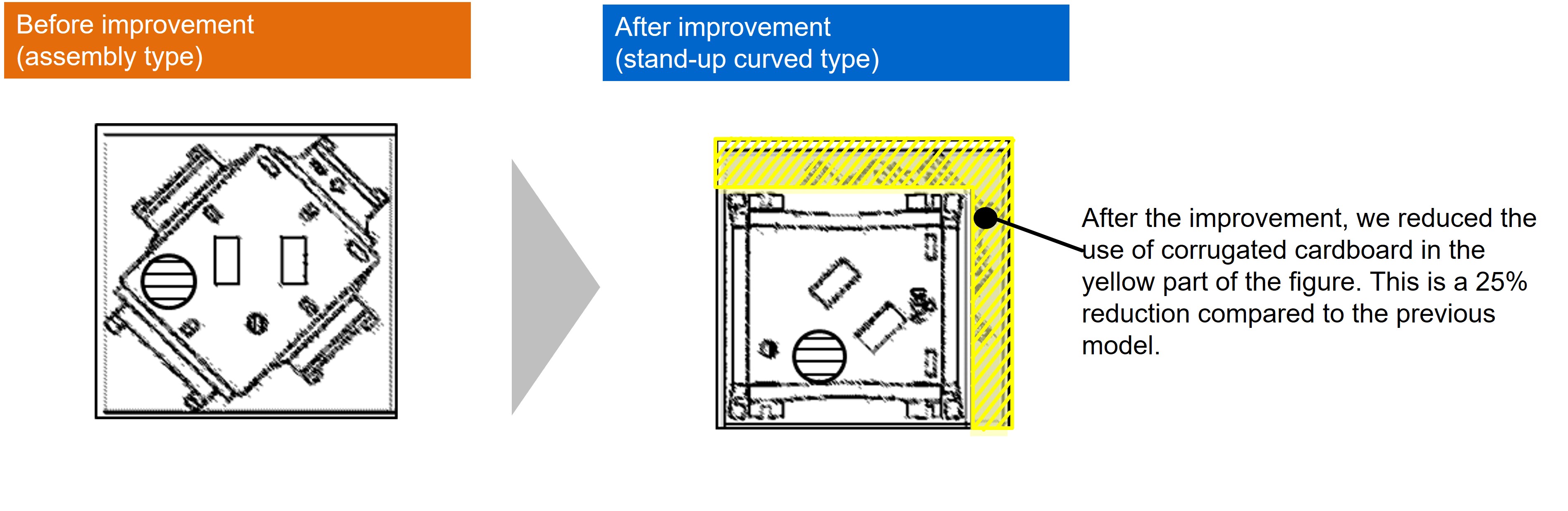

To solve this issue, we made the ruled lines arc inward, and made the ears of the four corners of the tray angled to provide more force to pull the rising part inward. The result was a product that retains rigidity while minimizing outward rebound. In addition, the use of high-density, thin corrugated cardboard made the product less likely to be crushed during conveyor transport. By changing how the cardboard was cut out, we made it possible to use the material without waste. As a result, the workload time was reduced by 20% and material costs were also reduced by 20% compared to the previous system. In addition, the amount of waste cardboard has been reduced by 25% to achieve environmentally friendly packaging.

※Ruled line: A line that is folded at a certain point of the corrugated board so that it can be bent neatly when it is assembled into a three-dimensional shape such as a box.